Guide to types of bricks in the UK

Bricks are synonymous with home construction in the UK. Their strength, versatility, and longevity are just a handful of reasons why bricks have been used in construction for thousands of years.

Sam Bull, Bricks & Blocks Sales Consultant at Elliotts, explores the various different types of bricks used within UK housebuilding and construction, and their properties.

What types of bricks are used in the UK?

The most commonly used bricks in the UK include facing bricks, engineering bricks, concrete bricks & common bricks, and special shaped bricks. Each has their own defined purposes within house building and construction.

Facing bricks

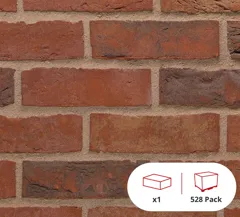

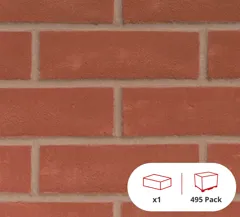

The most commonly used brick in house construction in the UK, facing bricks are the bricks you see on the external walls of homes and buildings.

These are typically made from clay or concrete although clay is much more common in the UK.

Facing bricks enhance the visual appearance of building and are available in a variety of colours, textures, styles and sizes depending on your preference or aesthetic requirements.

Facing bricks are manufactured using clay for durability and weather resistance, and also strength for load bearing support.

Modern day facing bricks are usually uniform in size at 215mm long x 102.5mm wide x 65mm high, according to British Standards.

What are the 4 main types of facing brick?

Wire-cut (extruded)

- Most commonly manufactured brick in the UK. A contemporary, modern day brick with a uniform shape and sharp arras.

- The bricks are made by cutting using a wire from a machine.

- Wire cut bricks are perforated.

Stock (soft mud)

- Made by throwing clay into a mould using traditional soft mud techniques, stock bricks are available in numerous colours, textures and sizes.

- Stock bricks will have some shape variation.

- Stock bricks are frogged.

Handmade

- Made by hand and will usually provide a more aged/traditional appearance with a coarse texture.

- Handmade bricks are likely to have shape variation and are usually available in metric and imperial sizes.

- Handmade bricks are frogged.

Waterstruck

- Made by using water to strike the mould for a different texture.

- Waterstruck bricks often have a soft texture and a characteristic lip on the brick.

- Waterstruck bricks are solid with no perforation or frog.

Engineering bricks

Where facing bricks have the looks, engineering bricks have the brawn.

Manufactured with impressive compressive strength and low water absorption, engineering bricks can be used in both below ground and above ground construction.

Engineering bricks are perforated to allow for mortar or steel bars and will generally be used where there is frequent contact with water, such as damp proof courses and sewers.

Solid engineering bricks are also available.

Class A vs Class B Engineering bricks

Engineering bricks are split into 2 classes; Class A and Class B.

Class A engineering bricks offer more compressive strength and a lower rate of water absorption and are likely to be used in specialist applications.

Class B engineering bricks offer lower compressive strength and a slightly higher rate of water absorption, but are more commonly used.

| Class A | Class B | |

|---|---|---|

| Minimum compressive strength | 125N/mm² | 75N/mm² |

| Maximum water absorption | 4.5% | 7% |

| Freeze thaw durability | F2 | F2 |

| Active soluble salts content | S2 | S2 |

Facing Engineering bricks

“If you want the best of both worlds, smooth facing bricks have the high strength of engineering bricks but have a more desirable finish for facing work”, says Sam.

"For example, facing reds, blues etc. can be used for housebuilding where a uniform, contemporary look is desired."

Common bricks

Not quite pretty or uniform enough to be used on the external walls of homes and buildings, common bricks will mostly be found forming internal walls.

Common bricks are usually cheaper than facing and engineering bricks for this reason, but what they lack in beauty and strength they make up for in versatility.

“Common bricks, are often not going to be seen and therefore a generic economical brick is a good option.”, says Sam.

“When someone requests common bricks, I’ll always ask what they’re being used for to make sure that it’s the right brick for the job.”

Common bricks can be left exposed, painted, or rendered over. Depending on the aesthetic you’re going for.

Special shaped bricks

Special shaped bricks are classed as any bricks that do not conform to the traditional size and shape of a brick and are usually used to enhance the appearance of a brick wall or structure.

Opting for special shaped bricks when constructing archways and canopies saves having to hand cut bricks to specific shapes; saving value time and money. Special shaped bricks are manufactured as solid, perforated, or frogged.

Readily available in red and blue colours, special shaped bricks are available in a range of different shapes to create a variety of designs.

AN – Angle and Cant

This type of special brick allows buildings or walls to carry an angle other than 90 degrees, including 30, 45, and 60-degree angles. They can also be used to create vertical and horizontal chamfered features on doors, windows, and corners, as well as decorative capping for walls.

BN – Bullnose

Bullnose bricks have a smooth rounded edge on one or two of their sides, providing gentle transitions for corners, doors, and window openings. These bricks look great visually and are widely used for making doorways, windows, and corners feel welcoming, as well as for decorative capping for walls.

AR – Arch

Arch bricks are double tapered along their length or width, meaning they can be used to form archways and other curved elements.

BD – Bonding

Cuboid bonding bricks are often used to fill gaps that would otherwise require a standard brick to be cut to size.

PL – Plinth

Angled at 45 degrees, these bricks are used to change the depth of the brickwork at the base of the wall. They have sharp cuts and shapes, making them ideal for detailing hard lines on window sills, kerbs, capping, and corbelling details.

Purpose made specials vs cut & bond specials

“A purpose made special brick involves us going direct to the manufacturer to make the brick”, say Sam Bull, Brick Sales at Elliotts.

“This can be a long process, but the result is more authentic of the original brick.”

A Cut & Bond special brick involves turning normal bricks into specials and usually involved two or more parts being bonded together.

“Normal bricks are cut with saws, bonded with a strong epoxy resin and then refaced”, says Sam.

“Cut & Bond specials have a quicker turnaround time and produce a great result. However, you may sometimes miss out on matching exact textures.”

Specialty bricks

Outside of normal construction bricks, there are a range of specialty bricks with specific uses; such as fire bricks and air bricks.

Fire bricks

Fire bricks, also known as refractory bricks, are most commonly used in projects where a structure will be exposed to high temperatures.

These dense bricks retain their form and strength under extreme temperatures when used to construct things like fire places, pizza ovens etc.

Fire backs

Acting much like fire bricks, a fire back is just one piece that fits into the back of your fireplace. Fire backs help your fireplace become more efficient by throwing more heat into the room.

Air bricks

Air bricks contain evenly spaced holes to allow air to pass through them, circulating the air. These will usually be used in homes and buildings with cavity walls and under suspended floors to prevent the build up of moisture which could cause rot and damp.

It’s important that air bricks aren’t deliberately blocked to continue to allow air to pass through.

Need to find the right bricks for your project?

Getting the right bricks for your project is essential to ensure they’re up to the job and fit in with your design plans.

We know how hard that can be, but we’ve got some incredible brick experts on hand to help. From sourcing the right bricks to matching into existing brick work for extensions, Sam and the rest of our brick specialists on hand to help!

Need a larger quantity of bricks?

Our teams specify sites from 10,000 bricks upwards, with direct-to-site delivery. We have supplied bricks for developments with hundreds of units under renowned National House Builders, and for smaller regional developers & self builders.

Pictured: Bargate Homes development in Stoneham - bricks supplied by Elliotts.

With over 2.2 million bricks in stock (including 500,000 Wienerberger bricks), you’ll find all the most popular styles stocked across our Elliotts branches.